Services

What we do

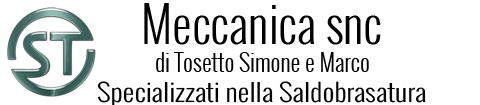

- Assembly and brazing of components supplied by the customer

- Drilling of the welded pieces, before or after welding

- Packaging kits

- Building of collectors for heating

In addition, we work closely with a leading company in Europe for bending and deformation of the copper tube and iron, and are therefore able to realize from the tube coil in a finished product.

Systems and Equipment

The production capacity of S.T. Meccanica uses the following equipment:

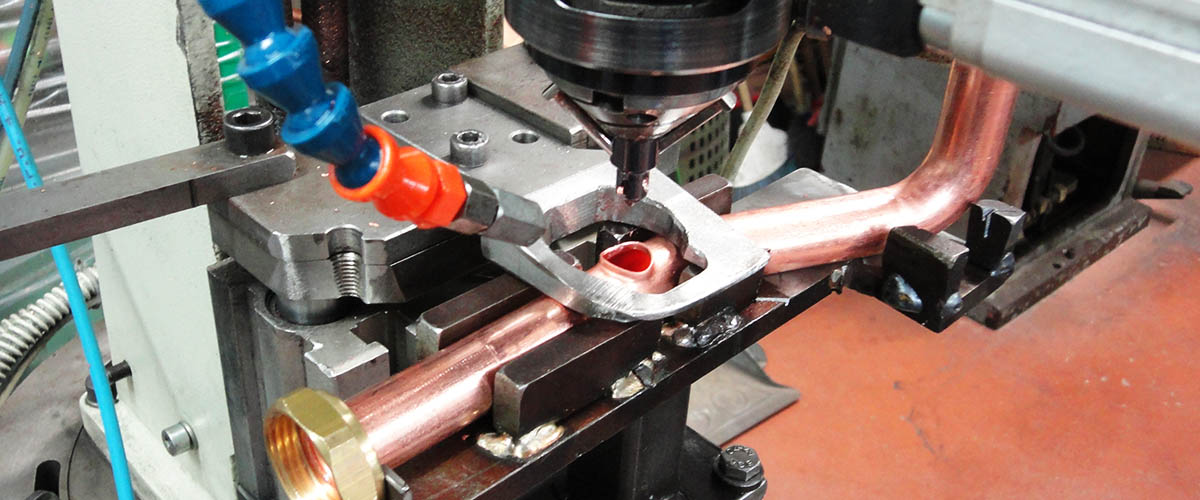

- 4 automatic brazing carousels to 6 stations with a preheating station and a piece ossipropano welding hydrogen / oxygen.

Production capacity from 120 to 200 PZ hours. - 3 manual welding carousels

- 1 Automatic drill T-Drill S-54 for the realization of the holes with collar 6 to 54mm

- 1 Plant for the production of hydrogen and oxygen used in the welding process

- 1 Machine for schimpatura kits (hot packaging)

- various drilling machines for drilling manual